Anpeng Self-cleaning series is designed for though to screen applications where blinding, pegging and clogging are a crucial problem. PU bands, made with 90 Shore A ( Poly Hardness ) polyurethane, bind together with steel wires allowing high-frequency vibration during screening and creating the self-cleaning effect. Each wire on self cleaning wire mesh vibrates at different frequency, which creates the self-cleaning effects of all our self-cleaning series. The theory behind is that a clogged material is able to pass through or bounce back up, because the different vibration frequency in wires is essentially creating alternating force from opposite side of the mesh. Anpeng self-cleaning series offers greater wear resistance and longer wear life, promises to significantly increase efficiency and lower cost of production.

Anpeng Self Cleaning Wire Mesh Series

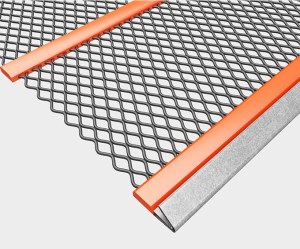

Diamond Opening Screen

Wire diameter: 1.2mm-12.7mm Opening size: 2.24mm~62.00mm This series produces high quality, consistent product and is effective in most general applications.

Diamond Opening Screen

Our most popular self-cleaning screen. It is similar to traditional square openings meshes, but with greater open area and increased throughput, providing precise material stratification and cleaner product.

Wave Opening Screen

Wire diameter: 1.2mm-12.7mm Opening size: 3.18mm~17.15mm This series delivers maximum throughput and ideal for removal of fines, producing a cleaner retained product.

Wave Opening Screen

Made with crimped wires placed parallel to each other, best used for severe blinding application, large open area offers effective sizing control, ideal for the removal of super fine materials and etc.

Triangle Opening Screen

Wire diameter: 1.2mm-12.7mm Opening size: 1.2mm~20.00mm This series is designed for finer size material and absorb greater impact while maintaining accurate sizing.

Triangle Opening Screen

Unique combination of crimped and straight wire form the triangular opening shape to absorb impact, and improve accuracy of sizing. This is a perfect replacement of traditional fine mesh.

Harp Screen

Wire diameter: 1.2mm-12.7mm Opening size: 4.0mm~25.00mm This series is designed in a standard piano wire screen style and most efficient in the dry screening of sand, gravel, topsoil and more.

Harp Screen

Designed to have the maximum open area, most efficiently in removing sand, gravel, topsoil, fines and etc.

Advantages of Anpeng Self-cleaning Screens

High Tensile Steel

that is abrasion resistant, which is ideal for applications facing significant wear such as filtering rocks, sand and gravel.

Stainless Steel

known for its high corrosion and temperture resistance, is extremely long-lasting and durable. It is ideal to be used in high humidity applications.

Polyurethane

is known for its high load bearing capacity in both tension and compression, and its abrasion and impact resistance property, Polyurethane is extremely wear proof in challenging applications even at very low temperture.

Anpeng Wire Mesh--Professional industrial screens manufacturers. We specialize in producing screening media for over 20 years, with the most cost-effective screen media options at top quality, much affordable price, and short delivery time, enabling our customers to be very competitive in the markets worldwide.

Location : No. 12 Weiyi Rd, East Wire Mesh Industrial Zone, Anping County, Hebei, China, 053600 Hebei,

Contact : com Apscreens, 022 87218226