Rotational mold is to first add plastic raw materials into the mold, and then the mold is continuously rotated along two vertical axes and heated. Under the action of gravity and thermal energy, the plastic raw materials in the mold are gradually uniformly coated and melted and adhered to the mold cavity. On the entire surface, it is formed into the required shape, and then cooled and shaped into a product.

Did not find what you were looking for~

Rotational Moulding Process

The basic rotational moulding process is simple. A powdered or liquid polymer is placed in a mold and heated. At the same time, the mold rotates both autonomously and metrically around a vertical axis, and then cools to form. At the beginning of the heating phase, if the material is in powder form, a porous layer is formed on the surface of the mold, which then gradually melts as it circulates, eventually forming a homogeneous layer of uniform thickness; if the material is in liquid form, it flows and coats the surface of the mold first, and then stops flowing completely when it reaches the gel point. The mold is then transferred to the cooling zone, where it is cooled by forced ventilation or water jets, and then placed in the work area, where the mold is opened and the finished part is taken away, followed by the next cycle.

Rotational Molding Advantages and Disadvantages

Design Advantages

The rotational moulding process steps provides us with more design latitude than other mold processes. With the right design concept, we can combine several parts into a complete mold, a practice that greatly reduces the high cost of assembly.

The rotomolding process also includes a range of inherent design thinking, such as how to reconcile sidewall thicknesses and how to reinforce external settings. If there is a need to add some ancillary design, then we can also add the reinforcement of the rib line to the design.

The rotomolding process infuses the product with the imagination of the designer. Designers can choose the best materials for the process, including those approved by the Food and Drug Administration. The additives put in the production process can effectively resist the aggression of the climate, static electricity interference and other external objective factors. In the design process, insertion ports, threads, handles, inverted traps, and perfect surface design are among the points of interest. Designers can also design multi-wall molds, which can be both hollow and filled with foam inside.

Cost Advantages

When cost is a consideration, rotomolding has a market advantage over other types of processes. When compared to blow molding and injection molding processes, rotomolding can easily produce parts of different sizes within a cost effective range. The tooling is also relatively inexpensive because it does not have some internal cores to complete. And in the absence of an internal core, just a small change can be made into another model.

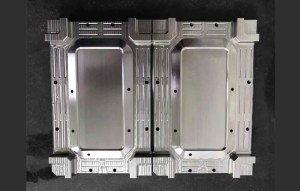

Because the parts are made under a high temperature and rotational process, unlike those formed under heavy pressure, rotomolding molds do not need to be specially processed to withstand the heavy pressure of the injection molding process.

Disadvantages

Limited variety of raw materials to choose from.

Raw materials require special processes and additives and need to be ground to a powder before they can be processed.

Some shapes are difficult to process.

Features of Rotational Moulding

In terms of molding process

(1) Suitable for molding large and very large parts. Since the rotational moulding process only requires the strength of the frame to support the material, the weight of the mold and the frame itself, and the closed mold force to prevent material leakage, there is no need to use very heavy equipment and molds even for processing large and very large plastic parts. Therefore, theoretically speaking, there is almost no upper limit for the size of products made by rotational moulding process.

(2) Suitable for the production of many varieties and small batches of plastic products - The simple structure and low price of the mold used in rotational moulding make it very convenient to change products.

(3) Suitable for processing large hollow products with complex shapes, which is incomparable to other molding processes.

(4) It is easy to change the color of plastic products. When the color of products needs to be changed, it is only necessary to clean the molding mold.

(5) The main disadvantages of rotational moulding are: large energy consumption, because in each molding cycle, the mold and mold frame need to undergo repeated heating and cooling; long molding cycle, because it mainly relies on static plastic conduction heat, so the heating time of rotational moulding is long; labor intensity is large, and the dimensional accuracy of products is poor.

Application of Rotational Moulding

With the development of the rotational moulding process, the scope of application of its products has been expanding, the application of rotational moulding products has been very wide, some representative applications can be cited as follows.

1.These plastic parts are widely used in water storage tanks, storage tanks for various liquid chemicals (such as acid, alkali, salt, chemical fertilizers, pesticides, etc.), gasoline containers (gasoline storage tanks and fuel tanks for automobiles and airplanes), battery shells, etc.

2. Automotive rotational moulding parts, mainly the application of polyethylene and polyvinyl chloride paste resin, rotational moulding of various pipe fittings, such as air conditioning elbow, backrest, handrails, etc.

3. Sports equipment and various substitutes. The main products are PVC paste rotomolded parts, such as water balloons, floating balls, bicycle seat cushions, small boats and shock absorbers between boats and docks. The roto-molded cross-linked polyethylene drums made from Philip's roto-molded grade cross-linked polyethylene tree "Maricxcl-100" can compete with metal drums, and they are chemically resistant and low maintenance. Rotomolded pallet, in the early 70s, in the United States, Japan and other countries have been commercialized; surfboards, boats, etc. are also often mentioned in the literature of rotomolded parts.

- Toys, mannequins, handicrafts, etc. Because the rotational moulding mold can be used for precision casting, electroforming and other processes; rotational moulding parts surface of the mold cavity surface fine structure "copy" effect is very good, so the rotational moulding method can make the product is quite exquisite and beautiful, so often used in the production of products with greater ornamental value, especially toys, models, handicrafts, etc..

COSMOPlat is a professional rotational moulding suppliers, mold manufacturer, we provide rotational moulding china, rotational moulding pdf, custom rotational molding, practical guide to rotational moulding, precision injection molding and etc. Want to know more? Please contact us.

Location : Innovation in A seat, No.1 Haier Road, Qingdao, Shandong Province, 266101 Qingdao,

Contact : Yokini Wang, 021 67696068