|

||||||||||||||||

|

Search / buy

Silver Flex Membrane Switches

|

|

Medical |

Military |

Industrial controls |

|

Aerospace |

Marine navigation |

Lighting & Lighting Controls |

|

CAN/BUS Controls |

Food Equipment |

Appliance |

|

Automotive |

Agricultural |

Sporting Goods |

|

Health & fitness equipment |

|

|

Silver Flex Membrane Switches Structure:Silver_Flex_Membrane_Switches.png

Overlay-Polyester is usually the first choice for membrane switch panel materials because its life will be a little longer than Polycarbonate. If it is simply a panel instead of a membrane switch, Lexan and Polyester are also good choices. The overlay is the most intuitive form of the human-machine interface. Niceone-tech will screen print or digital print on the back of the material, and they can also be used in combination. Special requirements such as the mirror silver effect are also feasible.

Overlay adhesive-As the first layer of adhesive paper under the panel, Acrylic adhesive is usually used, generally, the thickness is between 0.125-0.225mm. If it is an LGF membrane switch (to LGF membrane switch) structure, the thickness sometimes reaches 0.64mm.

Top Circuit Layer (Dome retainer): This layer usually has three functions: 1. As the Dome Retainer, it ensures that the Snap dome of the circuit layer will not form shrapnel movement due to triggering and closing, resulting in circuit failure and circuit wear. 2. Use 0.1-0.125mm Polyester printing conductive ink, carbon oil, and UV ink as the upper line. This layer structure can also be convex to make tactile feedback better. 3. Can be used as an ESD shielding layer.

Circuit Spacer (switch spacer): Both upper and lower lines are printed with conductive ink, usually thicker tape is used to separate the upper and lower lines to avoid direct conduction of the membrane switch. If the upper circuit is only used as a fixed layer, then the general thickness of the Overlay adhesive + Top Circuit Layer + Lower Circuit Layer should be greater than 0.4mm, otherwise, the panel will squeeze the shrapnel to make them feel worse. Unless the panel is convex, the four-layer structure is less than 0.4mm.

Lower Circuit Layer: The thickness of this layer circuit is usually 0.1-0.188mm. It can be printed with ink, carbon oil, and UV ink. LEDs can also be installed. Some membrane switch panels will choose the copper flex or Printing circuit Board as the circuit. Compared with Polyester, their performance will be more stable. More often applied to the medical and military industries. If it is copper flex or Printing circuit Board as a line, Niceone-tech can even install a variety of components on the line.

Rear Adhesive: There are many choices, but the most commonly used are the 3M200MP series or 3M300LSE. According to the different products of membrane switch lamination, Niceone-tech will recommend 3M300LSE if it needs higher viscosity.

Rigid Support Layer: This layer structure is generally used as the last layer of the membrane switch, which can make the structure of the membrane switch component more complete. Usually, the choice of materials is AL, FR4, PC, or steel. If AL is selected, nuts or feet may sometimes be added to the back of the product.

Contact : tech niceone-, 86 769 82608010

Good deal: buying from seller

We invite you to read our terms of use. You can also visit our FAQ section and see our information section on the risks associated with counterfeiting.

|

This page is about importers and exporters of Silver Flex Membrane Switches Search in a category : Search / buy Search in a category : flex, silver, switches, membrane |

Friday, May 16, 2014

Quantity : 5000000pcs - Price : $0.25-5/pc

Plastic Injection Parts Description Company Profile: We specilizes in developing and producing plastic injection parts and injection moulds for electrical appliances,home appliances,computers,telecommunication devices,pharmaceutical appliances, bathroom accessories and building...

Xiamen Karo Co.,Ltd

- karoplastic

- 361002 - Xiamen

- 0086 592 5135406

Wednesday, August 26, 2015

Quantity : 10000 - Price : 8 €

- Natural Himalayan salt lamp 4 sizes - Made of natural salt crystal from the Himalayan mountains. Works as an air purifier by emitting negative ions into the air and light therapy to reduce stress and increase energy. Each lamp is individually handcrafted and unique. Sits on...

Ecobis

- 42-510 - Tuliszow

- +48 7 30 88 19 53

Tuesday, February 17, 2026

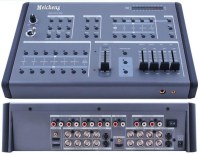

Applications : CMX-12 is a high definition digital AV Mixer, which is a simple type of HD/SD Video Mixer Editor to switch and effects. Each input BUS supports 6 inputs (2 x HDMI, 2 x Component, 2 x S-Video and Composite video) and also Background Color for special effect. The output...

Meicheng Audio Video Co., Ltd.

- meicheng

- 23511 - New Taipei City

- 886 2 82280311