Hot-rolling refers to a metalworking process in which the steel is rolled at above recrystallization temperature (usually exceeds 1000℉). Being heated past its recrystallization point, the steel can be properly formed, shaped, and produced in larger quantities. After being cooled at room temperature, the steel is normalized and cooled off, becoming a finished china hot rolled steel product. China hot rolled steel plate for sale not only has excellent strength and versatility but also is a cost-effective material than comparing with cold rolled steel.

As one of the excellent hot rolled steel sheet manufacturers in China, Cumic Steel (professional china hot rolled steel plate suppliers) produces different types of hot rolled steel with competitive price to meet the demands of clients.

Types of Hot Rolled Steel

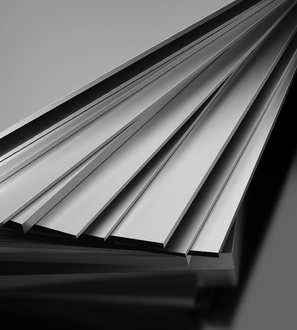

Hot Rolled Steel Plate

Hot rolling is a metal forming method that involves rolling the steel at a high-temperature rise above steel's recrystallization temperature.

Hot Rolled Steel Coil

Hot rolled steel coils are hot rolled steel made into relatively thin flat pieces and wound up into coils, resembling a wound steel strip.

Hot Rolled Steel Sheet

Hot rolled steel sheets are hot rolled steel made into relatively thin flat pieces. Hot rolled china carbon steel sheets are widely used in applications like home appliances.

Hot Rolled Checkered Coil

Hot rolled checkered coils are a type of hot rolled steel coils with rhombic (tear drop) shapes on its surface. Because of the rhombic patterns, the surface of the plates is rough.

H-Beam Steel

H-beam steel is a type of structural steel beam. It is named H-beam steel because of the capital H shape over its cross section with equal thickness in the two parallel flanges with no taper on the inside surface.

Angle Steel

Formed by bending a single angle in a steel piece, angle steel is the most basic type of roll-formed steel. angle steel is ‘L' shaped, usually bent at a 90° angle.

U-Channel Steel

U-Channel steel is rolled from steel sheet into U shapes. A piece of U-Channel steel consists of a wide "web" and two flanges. The flanges can either be parallel or tapered in shape.

UPN/UPE Steel

UPN or UNP is the short form that represents standardized stainless steel channels. UPN is often used in multiple kinds of industrial applications such as construction and machinery.

IPEAA Steel

IPEAA steel refers to a type of structural steel beam made of rolled steel with an “I” shape. IPAA steel has good plasticity, toughness, machinability, and weldability.

Wire Rod Steel

Wire rod steel refers to a type of semi-finished long steel product manufactured by hot rolling billets on continuously rolling mills. It is characterized by having a round cross-section.

Rebar Steel

Rebar, also frequently referred to as reinforcing steel or reinforcement steel, is a type of steel bar or mesh of steel wires used as a tension device in reinforced concrete and masonry structures to strengthen the concrete under tension.

DIFFERENT USAGE OF TYPES OF HOT ROLLED STEEL PRODUCTS

1.Steel for structure

It is mainly used in the production of steel structural parts, bridges, ships and vehicles.

2.Weathering steel

With adding special elements (P, Cu, C, etc.), weathering steel has good corrosion resistance and atmospheric corrosion resistance, and is used for the production of containers and special vehicles, and also for building structures.

3.Steel for automobile structure

It has high strength steel plate with good stamping performance and welding performance, used for the production of frame, wheel, etc.

4.Hot rolled special steel

General mechanical structure uses carbon steel, alloy steel, tool steel, after heat treatment engineering for the production of various mechanical parts.

5.Cold rolled raw plate

It is used in the production of various cold rolled products, including CR, GI, color coated plates, etc.

6.Steel plate for steel pipe

With good processing performance and pressure strength, it is used for the production of high-pressure gas pressure vessels filled with LPG, acetylene gas and various gases with an inner volume of 500L or less.

7.Steel plate for high-pressure vessels

With good processing performance and pressure strength, it is used for the production of high-pressure gas pressure vessels filled with LPG, acetylene gas and various gases with an internal volume of 500L or less.

8.Stainless steel plate

Stainless steel has good corrosion resistance, mainly used in the food industry, surgical equipment, aerospace, petroleum, chemical and other industries.

WELDING NOTICE OF HOT ROLLED CARBON STEEL FLAT PRODUCT

1.Due to the good welding performance of hot rolled carbon steel flat product, in the condition of not thick plate, and the welding requirements are not too high, the choice of AC spot welder can achieve the welding requirements.

2.If the cost of equipment allows, try to use medium frequency inverter spot welder to spot weld mil steel plate. The welding effect is better, and the fusion nucleus and welded joints will be more perfect.

3.There are cold-rolled steel plates and hot-rolled steel plates. Cold-rolled steel plates do not need special cleaning before welding, while hot-rolled steel plates must be cleared of oxidation, rust, oil and other impurities on the surface.

4.If the capacity of the spot welder used allows, it is suggested that hard specification welding to reduce the effect of heat diffusion on the product, and also to reduce product distortion.

HOT ROLLED CARBON STEEL OVERVIEW

Hot rolled carbon steel plates are widely used in many specialized mechanical equipment and large structural components in the manufacturing industry, for example, in the engineering, energy and mining machinery industries, where many products use steel plateswith thicknesses of 6-20mm. Some of these hot rolled carbon steel plates are flat sheets without hollow cores, while most are 30% porosity plates. Their specifications and sizes vary depending on the product and application. These carbon steel plates are cut by plasma or oxygen, which will leave different degrees of flying edges, slag and burrs on the cut surface. These must be removed, otherwise the aesthetics and usability of the finished product will be affected.

HOT ROLLED STEEL PRODUCTS VS COLD ROLLED STEEL PRODUCTS

·Cold rolled steel products are hard, relatively difficult to process, but not easy to deformation, higher strength.

·Hot rolled steel products strength is relatively low, and the surface quality is poor (oxidation/low finish), but it has good plasticity, generally for the thick plate. Cold rolled steel products have high strength, high hardness, high surface finish, generally for the thin plate, which can be used as a stamping plate.

·The mechanical properties of hot rolled steel products are far from cold rolled steel product, but hot rolled steel products have good toughness and ductility.

·Cold rolled steel products due to a certain degree of hardening, low toughness, but can achieve a better yield to strength ratio, used to cold bending spring and other parts, while the yield point is closer to the tensile strength, so the use of the process of danger is not foreseeable, in the load exceeds the allowable load is prone to accidents.

As one of steel china companies, we will provide more types of related products for sale, if you have needs, please contact us.

Location : "CUMIC Shanghai (HQ):Unit 2006-2015, City Centre Tower A, 100 Zunyi Road, Changning District, Shanghai, ChinaCUMIC Dubai:P.O. Box 53791, Unit 2809 JBC01 Jumeirah Lakes Towers, Dubai, UAECUMIC Houston:1400 Broadfield Blvd, Suite 200, Houston, Texas 77084, , 200051 Shanghai,

Contact : Tao David , 86(21)56118383