|

|

|

B2B Services

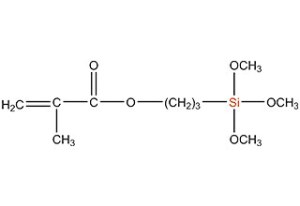

Acyl Silanes

|

|

This page is about importers and exporters of Acyl Silanes Search in a category : B2B Services Search in a category : acyl, silanes |

Friday, March 27, 2015

Quantity : 25TON - Price : USD 850/TON

Introduction: Fiberglass Assembled Roving for Filament Winding are compatible with polyester, vinyl ester and polyurethance resins.It is an E-glass roving produced by directly winding a certain number of individual fibers form the bushing without twist,it is coated with a silane-based...

HEBEI YUYIN TRADE CO., LTD.

- 050000 - Shijiazhuang

- 0311 67805175

- 0311 67805505

Friday, March 27, 2015

Quantity : 25TON - Price : USD770/TON

Introduction: Fiberglass chopped strands for cement is made from E-glass, with Silane sizing coated, or other dedicated sizing. Because of its high strength and alkali-resistant property, this fiberglass chopped strands is an idea material for cement reinforcement. Product Application...

HEBEI YUYIN TRADE CO., LTD.

- 050000 - Shijiazhuang

- 0311 67805175

- 0311 67805505

Friday, March 27, 2015

Quantity : 24 TON - Price : USD 770 / M2

BRIEF INTRODUCTION: Fiberglass chopped strand was the main raw material for producing brake lining, brake pads and other friction materials, it is the new product for replacement of asbestos for environmental protection property. It was widely used in the fied of auto industry....

HEBEI YUYIN TRADE CO., LTD.

- 050000 - Shijiazhuang

- 0311 67805175

- 0311 67805505